Partnering with industry leading architects, builders, and consultants

24 Years of Innovation

About Us

Over the past two decades, ShapeShift Technologies has built its reputation as the preferred partner for the world’s leading architects, consultants, and Tier 1 builders, amassing a portfolio of over 320 landmark projects across 16 countries.

Through a vertically integrated design to manufacture process, ShapeShift delivers intelligent, sustainable, low-risk solutions by leveraging cutting-edge aerospace technology and precision manufacturing techniques at scale.

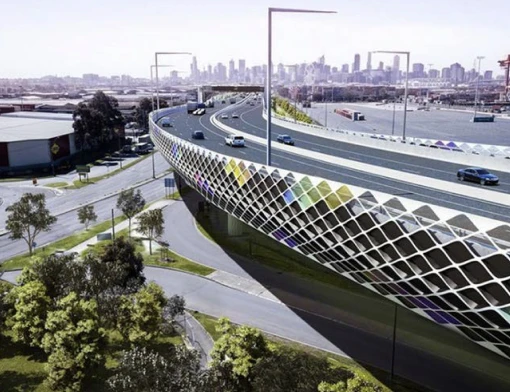

Portfolio

Over 300 project completed globally

ShapeShift prides itself on providing innovative solutions for projects of any size, or complexity, be it robust civil infrastructure, or ambitious architectural designs. The level of expertise and attention to detail is exemplified by our esteemed client list and long history of award-winning projects.

Architectural

Internal & External

Public Artwork

Civil Infastructure

Formwork

Next Generation Reinforced Materials

Product

Substrates

ShapeShift’s Fiber Reinforced Solutions, known as ShapeShell, combine the latest aerospace-grade materials with precision manufacturing techniques and are renowned for their exceptional structural integrity, performance, durability and affordability.

ShapeShell’s next generation solutions outperform conventional materials across all key areas, while meeting global testing certifications, ISO 9001 design and manufacturing standards, and offering up to 50 year warranty.

ShapeShell-RT (Reinforced Thermoset)

Next Generation : GFRP, GRP, FRP, Fiberglass, Carbon Fiber, Kevlar.

- Advanced Fibers in thermoset resin.

- 5 times stronger than Aluminum

- Modern fibers in a thermoset resin.

- 130% lighter than GFRC.

- Latest non-woven multi-axial fabrics for efficientload transfer.

ShapeShell-RC (Reinforced Concrete)

Next Generation : GFRC, GRC, Glass Reinforced Concrete

- Advanced Fibers in a cementitious matrix.

- 50% stiffer than standard GFRC

- Modern fibers in a geopolymer matrix.

- 100% lighter than precast concrete panels.

- Commingled nano raw-material additivesand fibers.

ShapeShell-RG (Reinforced Gypsum)

Next Generation : Glass Reinforced Plaster

- Advanced Fibers in geopolymer matrix.

- Flexural Strength equivalent to GFRC

- Modern fibers in a gypsum matrix.

- 30% lighter than GFRC.

- Commingled nano raw-material additivesand fibers.

If You Can Dream It

We Can Create It

High Performance, Low Risk

The ShapeShell Advantage

Easy To Install

- Fewer connections, faster install.

- Incorporates off-the-shelf attachments.

- Tolerances are designed into solutions.

- Delivered on load-rated stillages.

- Minimal expansion joins

Meets Architectural Intent

- Limitless shapes (utilizing AI software).

- Endless surface finish and color possibilities.

- Lowest embodied energy.

- 400% lower greenhouse gas

emissions.

Quality Assurance

- Aerospace manufacturing practices.

- Consistent mechanical properties.

- Reduced reaction loads.

- Unmatched impact and fatigue properties.

From Design to Delivery

Our process

We thrive on the collaborative path of developing solutions and enjoy the small projects as much as the towering façade projects. From the simple to the complex, we want to be your “new construction age” partner.